Our Products

Single Conical Spring Deal

Type : 11U

Series 11U is a single conical helical spring unbalanced seal with ‘O’ ring as secondary sealing member. Various seal face materials and elastomers can be offered for wide service application. As the torque transmission is done by conical helical spring, these seals are dependent of the direction of rotation. Direction of rotation is seen from the drive end of the shaft. Clockwise rotating shaft requires right handed spring and anti-clockwise rotating shaft requires left- handed spring. For easier fitting the conical helical spring should be pushed on the shaft with a twisting motion in the sense of the spring winding. This movement enlarges the diameter of the spring, enabling easy fitment.

Applications

- Water & Circulation Pumps

- Chemical Process Pumps

- Sewage & Submersible Pumps

- MOC For Seal Faces:

- Rotary: Tungsten Carbide, Silicon Carbide.

- Stationary: Ceramic, Carbon

Design

- Single Acting. Inside Mounted.

- Dependent of the Direction of Rotation.

- Unbalanced.

Hardware Material

- Compression Unit:-5.5.316

- Spring:-5.5.316

- Sewage & Submersible Pumps

- Secondary Material: Viton/PTFE/GFT

Operation Parameters

- Pressure:- Upto 10 Bar

- Speed: 10m/sec

- Temperature: -20° to 180°c

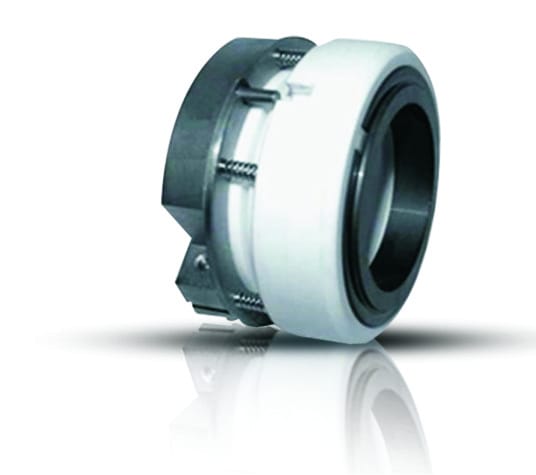

Teflon Bellow Seal

Type : 21C & 21R

SERIES 21C and 21R are designed for extremely corrosive chemicals, including concentrated acids and salts, strong oxidising and reducing agents, and chemically active organic compounds. All components which come in contact with the liquid being sealed are made of chemically inert material. Metallic components clamping ring and springs are located outside the pump stuffing box.

Type : 21C

In this seal type Glass filled PTFE face is composite moulded with highly flexible PTFE bellows.

Type : 21R

It is a seal similar to Type 21C in design with replaceable seal ring. This permits easy removal and replacements of the seal ring, a cost saving feature. In this type different face materials can be used to handle a wide range of corrosive and abrasive liquids.

Applications

- For Highly Corrosive clear/abrasive liquids

- From low to medium pressure

- MOC For Seal Faces:

- Rotary :- Glass Filled Teflon / Silicon Carbide / Carbon

- Stationary: Silicon Carbide / Ceramic.

Design

- All Contact Parts are Non-Metallic.

- Externally Mounted Design.

- Multiple Spring Arrangement for Uniform Loading.

- Independent of direction & Rotation.

Hardware Material

- Compression Unit:- Glass Filled Teflon

- Spring:- S.S.316/Hast Alloy 'C'

- Thrust Ring :- S.S.316

- Allen Bolt: 5.5.316

- Clamp - 5.5.316

- PTFE Bellow

Operation Parameters

- Pressure:- Vacumm to 5 Bar

- Speed: Upto 12 m/s

- Temperature:- 45°c to 120°c

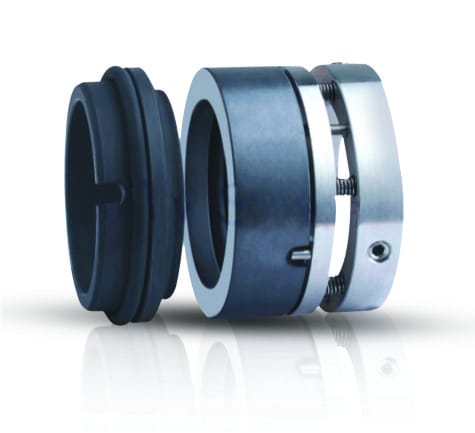

Multispring Seal

Unbalance Wedge / 'O' Ring Type

Type: 30U and 35U

Series 300 and 35U are multiple spring-unbalance seal with Wedge as secondary sealing member in series 300 and ‘O’ Ring as a sealing member in 35U. Various face material & elastomers can be offer for wide service application. The compact design of seal permits their use in all types of centrifugal pump. As all parts are interchangeable, one can convert series 300 to series 35U by changing only seal ring, secondary packing and mating ring packing. This concept is ideal for stock rationalization.

These Seals can be easily assemble or dismantled through circlip provided & can be change to Balance version by merely changing the carbon face only & can be provided with single, double or tandem arrangement with external seal support systems & devices

Type 35U

Secondary Seal Material: Viton / Buna / EPDM or Neoprene ‘O’ Ring in order to ensures less shaft fretting due to capacity for flex and roll. ‘O’ Ring Seals are preferred where elastomer are suitable for process fluid.

Туре 30U

Secondary Seal Material: PTFE/ GFT Wedge in order to ensures seal operation on high temperature and Chemical Application

Applications

- For Clear Corrosive / Non-Corrosive liquids from low to high Pressure range.

- MOC For Seal Faces:

- Rotary: Carbon/GFT/Tungsten Carbide / Silicon Carbide

- Stationary: Silicon Carbide / Ceramic/ Tungsten Carbide / Stellite.

Design

- Internally Mounted Compact Design.

- Multispring Arrangement Ensures Uniform Loading

- Mechanical Locking Ensures Positive Drive

- Independent of Direction of Rotation.

Hardware Material

- Compression Unit: 5.5.316

- Spring: 5.5.316/Hast Alloy 'C'

- Thrust Ring: 5.5.316

- Grub Screw: 5.5.316

Operation Parameters

- Pressure: 11 Kg/cm2

- Speed: Upto 25 m/s

- Temperature: upto 260°c

Multispring Seal

Balance - Wedge / 'O' Ring Type

Type: 40B and 45B

Series 408 & 458 are multiple spring balance seal with O-Ring as secondary sealing member in series 408 & wedge as a sealing member in 458. Various face material & elastomers can be offer for wide service application. The compact design of seal permits their use in all types of centrifugal pump. As all parts are interchangeable, one can convert series 408 to series 458 by changing only seal ring, secondary packing and mating ring packing. This concept is ideal for stock rationalization

Type 40B

Secondary Seal Material: Viton / Buna / EPDM or Neoprene “O” Ring in order to ensures less shaft fretting due to capacity for flex and roll. “O” Ring Seals are preferred where elastomer are suitable for process fluid.

Туре 45B

Secondary Seal Material: PTFE/GFT Wedge in order to ensures seal operation on high temperature and Chemical Application

Applications

- For Clear Corrosive / Non-Corrosive liquids from low to high Pressure range.

- MOC For Seal Faces:

- Rotary :- Carbon/GFT / Tungsten Carbide / Silicon Carbide

- Stationary :- Silicon Carbide / Ceramic/ Tungsten Carbide / Stellite.

Design

- Internally Mounted Balanced Compact Design..

- Multispring Arrangement Ensures Uniform Loading.

- Mechanical Locking Ensures Positive Drive

- Independent of Direction of Rotation.

Hardware Material

- Compression Unit :-S.S.316/Hast Alloy 'C' / Alloy-20

- Spring:- 5.5.316/ Hast Alloy C/ Alloy-20

- Thrust Ring:- 5.5.316

- Grub Screw:- 5.5.316

Operation Parameters

- Pressure:- 30 Bar

- Speed: Upto 3500 rpm

- Temperature: -20°c to 180°c

Reverse Balance Seal

Type: 50

Series 50 is multiple spring externally mounted balanced seal with ‘O’ ring as secondary sealing member. The unique feature of this type of seal is that, it eliminates the shaft step or sleeves for balancing. Various seal face materials and elastomers can be offered for wide service application. This seal can also be used for corrosive services as the metallic components i.e. Retainer, Spring, Thrust Ring etc do not come in contact with liquid to be sealed. The compact design eliminates the requirement of extra radial & axial space for its installation.

Applications

- Corrosive Chemicals

- Hydrocarbons

- Light Chemicals

- MOC For Seal Faces:

- Rotary: Carbon/Silicon Carbide/

- Glass Filled Teflon

- Stationary: Silicon Carbide/Ceramic/Stellite

Design

- Single Acting

- Outside Mounting

- Independent of direction and rotation

- Balance

- Mechanical loading ensures positive drive

Hardware Material

- Compression Unit: S.S.316/Hast Alloy 'C' / Alloy-20

- Spring: S.S.316/Hast Alloy 'C

- Thrust Ring: 5.5.316/Hast Alloy C/Alloy-20

- Grub Screw :-5.5.316

- Secondary Material :- Viton/ Neoprene/Buna/Kalrez "O' Ring ensures less shaft fretting due to capacity of Flex & Roll

Operation Parameters

- Pressure:- Max 10 bar

- Speed: Upto 25 m/s

- Temperature:-20° to 180°c

Single Coil Mechanical Seal

Type: 60U and 65U

Series 60U and 65U are single coil spring unbalance seal with O-Ring as secondary sealing member in series 60U and V packing as a sealing member in 65U. Various face material & elastomers can be offer for wide service application. The compact design of seal permits their use in all types of centrifugal pump. Non-clogging spring design enables these seals to be reliably used in situations involving abrasive, corrosive & viscous fluids generally handled by high Temperature pumps.

Type 60U

Secondary Seal Material: Viton / Buna / EPDM or Neoprene ‘O’ Ring in order to ensures less shaft fretting due to capacity for flex and roll. ‘O’ Ring Seals are preferred where elastomer are suitable for process fluid.

Type 65U

Secondary Seal Material: PTFE V Packing ensures the seal usage in mostly all chemical applications.

Applications

- For Slurry / high viscous liquid/ abrasive services from low to medium pressure & temperature range. It is suitable for various industries such as General Chemicals, Petrochemicals, Light Hydrocarbons, Refineries and Fertilizers etc.

- MOC For Seal Faces:

- Rotary:- Carbon/Tungsten Carbide / Silicon Carbide

- Stationary: Silicon Carbide / Ceramic / Tungsten Carbide / Stellite

Design

- Internal Mounted Unbalance Type

- Single Coil Spring Eliminates Spring Clogging

- Mechanical Locking Ensures Positive Drive

- Independent of Direction of Rotation

Hardware Material

- Compression Unit: 5.5.316/ Hast Alloy 'C' / Alloy-20

- Spring :- S.S.316/ Hast Alloy 'C' / Alloy-20

- Grub Screw :- 5.5.316

Operation Parameters

- Pressure: 30 Bar

- Speed: Upto 25 m/s

- Temperature: -20°c to + 180°c

MultiSpring High Pressure Seal

Type: 70

Series 70 are Multispring High Pressure seal with O-Ring or PTFE V packing as secondary sealing. They are very commonly used mechanical seals for clear liquids in most equipments. They are Bi-directional pusher type mechanical seals suitable to all type of elastomers. Such mechanical seals are available in Un-balance design for low pressure and balance design for high pressure applications. They can be designed in double configuration for toxic and hazardous liquids.

Series: 70

Secondary Seal Material:

- Viton / Buna / EPDM or Neoprene 'O' Ring in order to ensures less shaft fretting due to capacity for flex and roll.

- PTFE V Packing ensures the seal usage in mostly all chemical applications.

Applications

- For Non-Crystallizing acid, Alkali, Salt, Low viscosity oil, Monomer, Hydrocarbon, Low slurry water, sea water, etc.

- MOC For Seal Faces:

- Rotary: Tungsten Carbide / Silicon Carbide / Ceramic

- Stationery : Carbon / Stellite

Design

- All Contact Parts are Non-Metallic.

- Externally Mounted Design.

- Multiple Spring Arrangement for Uniform Loading.

- Independent of direction & Rotation.

Hardware Material

- Compression Unit:- Glass Filled Teflon

- Spring:- S.S.316/Hast Alloy 'C'

- Thrust Ring :- S.S.316

- Allen Bolt: 5.5.316

- Clamp - 5.5.316

- PTFE Bellow

Operation Parameters

- Pressure:- Vacumm to 5 Bar

- Speed: Upto 12 m/s

- Temperature:- 45°c to 120°c

Dry Running Mechanical Seal

Type: 80D

Series 80D is an outside mounted dry running single seal designed specifically for use on top-entry agitator and mixer services. The contacting dry running design eliminates the need for a buffer fluid system while handling run out up to 0.150″ FIM.

Features/Benefits

- Self-lubricating carbon or filled PTFE seal face runs completely dry without cooling - Long life and reliability are achieved in the dry vapour space at the top of the mixer vessel while eliminating product contamination from liquid barrier fluids.

- Flexible rotor design compensates for shaft misalignment -Clearances, drive design, seal face dimensions, and O- ring configuration were optimized for the high run-out requirements of mixers and similar equipment. Simple, rugged drive design that withstands shaft movement vibration & deflection

- Double O-ring mounted stator prevents distortion.

- Non-metallic collar option provides superior chemical resistance.

- Since no auxiliary equipments are needed for installation, it is very cost effective and economical.

Applications

- Use in Top Entry Agitator & Mixers in Pharmaceuticals & Chemical Industries.

- MOC For Seal Faces:

- Rotary Face: Carbon

- Stationary Face:- Ceramic / Tungsten Carbide / Silicon Carbide.

Design

- Single Externally Mounted ID Balanced Seal

Hardware Material

- Metal Parts :- 5.5.316

- Secondary Material :- Viton / Nitrile / PTFE.

Operation Parameters

- Pressure:- Full Vacumm to 200 PSI

- Speed: Upto 350 RPM

- Temperature: Ambient to 180°c

Cartridge Double Mech Seal

Type: 90C

Series 90C is factory assembled cartridge units for Agitators, Reactor & Glass-Lined Vessels. The seals are designed for handling severe services including products emitting toxic vapour during reaction process. The design incorporates bearing located very close to the seal. This standard feature effectively arrests the shaft whip for smooth and trouble free operation enabling enhanced seal life. The cooling jacket, also a standard feature, helps to maintain cool environment around the seal. Large clearance between rotating shaft/sleeve and mating ring permits higher deflection of the shaft, invariably associated with top entry agitators.

Applications

- Corrosive Services & Products

- Pharmaceuticals

- MOC For Seal Faces:

- Inboard Seal:- Carbon v/s Ceramic/T.C. / SIC or Stellite

- Outboard Seal:- Carbon v/s Ceramic / T.C./ SIC or Stellite

Design

- Double Acting Back to Back

- Independent of Direction & Rotation

- Balanced & Unbalanced Version

- Operated with Pressure Barrier Fluid

- No Metals Parts in Contact with Media or Vapour

Hardware Material

- Metal Parts :- 5.5.316

- Secondary Material: Viton / PTFE/GFT

Operation Parameters

- Pressure:- Upto 40 Bar

- Speed: 350 RPM

- Temperature:- Ambient to 220°c